Brushless dc motor

The brushless dc motor uses semiconductor switching devices to realize electronic commutation. It has the advantages of high reliability, no commutation spark, low mechanical noise, etc.

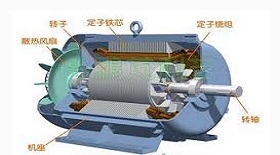

Brushless dc motor is composed of permanent magnet rotor, multipole winding stator and position sensor. According to the change of rotor position, position sensing is along a certain sequence of stator winding current converter. The working voltage of the stator winding is provided by the electronic switch circuit that controlled by the output of the position sensor.

There are three types of position sensor: magnetic, photoelectric and electromagnetic. A brushless dc motor uses a magnetic-sensitive position sensor, whose magnetic sensor components (such as hall element, magnetic-sensing diode, magnetic-sensing expole tube, magnetic-sensing resistor, or special integrated circuit, etc.) are installed on the stator assembly to detect changes in magnetic field, which caused by permanent magnet and rotor rotation.

The brushless dc motor using the photoelectric position sensor is configured with the photoelectric sensor in a certain position on the stator assembly. The rotor is equipped with a screen, and the light source is light-emitting diode or small light bulb. When the rotor rotates, the light-sensitive components on the stator will produce impulse signals at intervals of a certain frequency due to the effect of the mask.

Using electromagnetic position sensor brushless dc motor in the electromagnetic sensors are installed on the stator component parts (such as the coupling transformer, close to switch, LC resonance circuit, etc.), when the permanent magnet rotor position changes, electromagnetic effect will make the electromagnetic sensor produces high frequency modulation signal (the amplitude changes with the rotor position).